Một trong những khía cạnh môi trường có ý nghĩa tại CFC là việc quản lý chất thải rắn (CTR) bao gồm chất thải nguy hại (CTNH) và chất thải sinh hoạt (CTSH), chất thải rắn công nghiệp thông thường. Đây là một công việc đầy khó khăn, thách thức với Công ty vì ngoài sự nghiêm túc, tự giác thực hiện đúng quy định của CBCNV còn có sự giám sát rất chặt chẽ của cơ quan quản lý nhà nước, trong khi Công ty có số lượng các công đoạn phát sinh CTR, CTNH, CTSH trải dài từ khâu khai thác mỏ tới xuất hàng, với hàng chục chủng loại, khối lượng phát thải lớn với hàng trăm tấn CTNH, chất thải rắn công nghiệp thông thường (CTRCNTT) mỗi năm, với sự tham gia của hàng ngàn nhân viên và nhà thầu, đặt biệt trong các dịp đại tu, sửa chữa lớn.

Tuy nhiên, với sự quan tâm đặc biệt của ban lãnh đạo và sự nghiêm túc, chuyên nghiệp của CBCNV, Công ty đã triển khai áp dụng tiêu chuẩn ISO 14001 từ những năm 2000. Nhờ đó CFC đã tiếp cận với phương pháp quản lý tiên tiến theo tiêu chuẩn quốc tế.

Công ty đã hoạch định từ việc thiết lập qui trình quản lý CTR, CTNH, phân công rõ vai trò, trách nhiệm của các bên liên quan, biên chế 2 kỹ sư môi trường giám sát trên hiện trường, quản lý bằng cơ sở dữ liệu các mã chất thải phát sinh cũng như trong chuyển giao, xử lý ; mạng lưới phân loại, thùng chứa thu gom bao gồm hàng trăm chiếc với mã màu, nhãn hướng dẫn; hệ thống kho lưu trữ theo đúng tiêu chuẩn quốc gia được xây dựng bao gồm 15 nhà kho kết cấu bê tông, có mái che, cửa kho đảm bảo kín nước, gắn mã từng loại chất thải rõ ràng theo TCVN, trang bị hệ thống rãnh gom, hệ thống bình chữa cháy với tổng diện tích 375 m2 tại khu vực nhà máy chính, 18 m2 tại khu vực mỏ.

Hệ thống kho lưu trữ chất thải rắn, chất thải nguy hại đạt chuẩn, chuyên nghiệp.

Trong công đoạn chuyển giao và xử lý, Công ty cũng tìm kiếm và ký kết hợp đồng với những đối tác là các Công ty chuyên nghiệp, có đủ năng lực theo đúng qui định của Bộ TNMT.

Hàng năm, khi xây dựng kế hoạch bảo vệ môi trường, ngân sách cho hoạt động thu gom, chuyển giao và xử lý CTR, CTSH và CTNH luôn được ưu tiên. Kinh phí thực hiện hàng năm lên tới 400 đến 500 triệu đồng.

Mạng lưới phân loại, thùng chứa thu gom bao gồm hàng trăm chiếc với mã màu, nhãn hướng dẫn

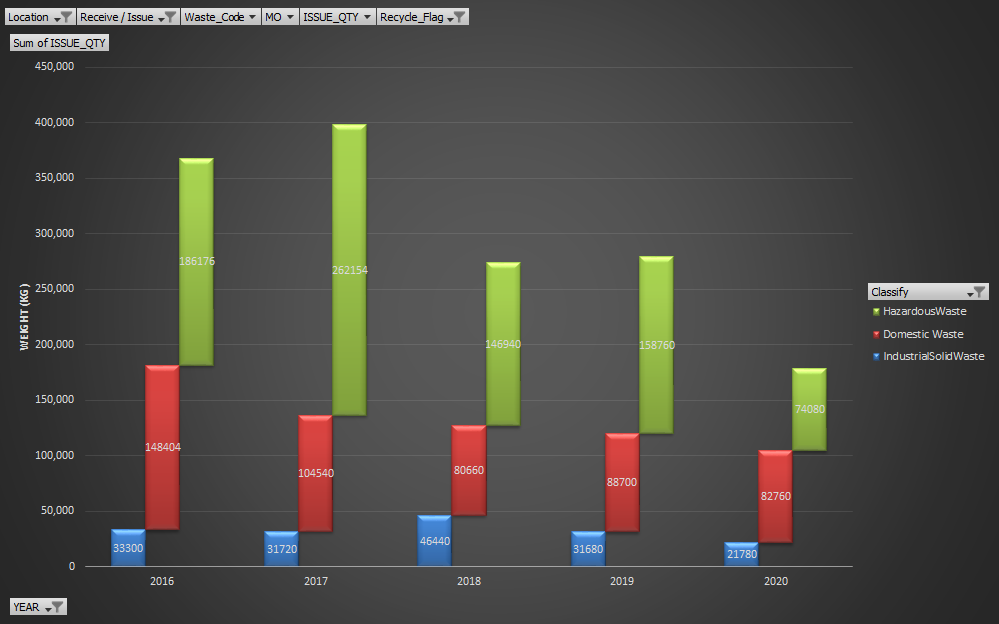

Việc giảm thiểu số lượng CTR, CTSH, CTNH cũng được Công ty đưa vào mục tiêu bảo vệ môi trường hàng năm và tuyên truyền tới toàn thể CBCNV và nhà thầu. Công ty cũng áp dụng triệt để các biện pháp giảm thiểu chất thải như sử dụng khay hứng dầu thay cho giẻ dầu, phân loại nguồn phát thải để tránh phát sinh CTNH do bị dính dầu, tách biệt chất thải rắn có khả năng tái chế khỏi CTNH. Khối lượng phát thải được báo cáo định kỳ tới lãnh đạo Công ty và xem xét trong cuộc họp giao ban hàng tháng.

Quản lý bằng cơ sở dữ liệu các mã chất thải phát sinh cũng như trong chuyển giao, xử lý

Các thủ tục như đăng ký chủ nguồn thải, các chứng từ chuyển giao chất thải, báo cáo hàng năm về khối lượng phát thải được Công ty nghiêm túc thực hiện và báo cáo cơ quan quản lý Nhà nước.

Đặc biệt, trong quá trình quản lý, Công ty cũng nhận được sự hỗ trợ, hướng dẫn kịp thời của các cơ quan quản lý nhà nước như Sở TNMT TP Hải Phòng, Bộ TNMT.

Với những yếu tố trên đây, vượt qua những khó khăn thách thức, công tác quản lý CTR, CTSH và CTNH tại CFC đã đạt được những thành tựu đáng kể: khối lượng chất thải năm 2020 đã giảm 51,50% so với năm 2016, góp phần đáng kể vào công tác bảo vệ môi trường chung của Công ty.